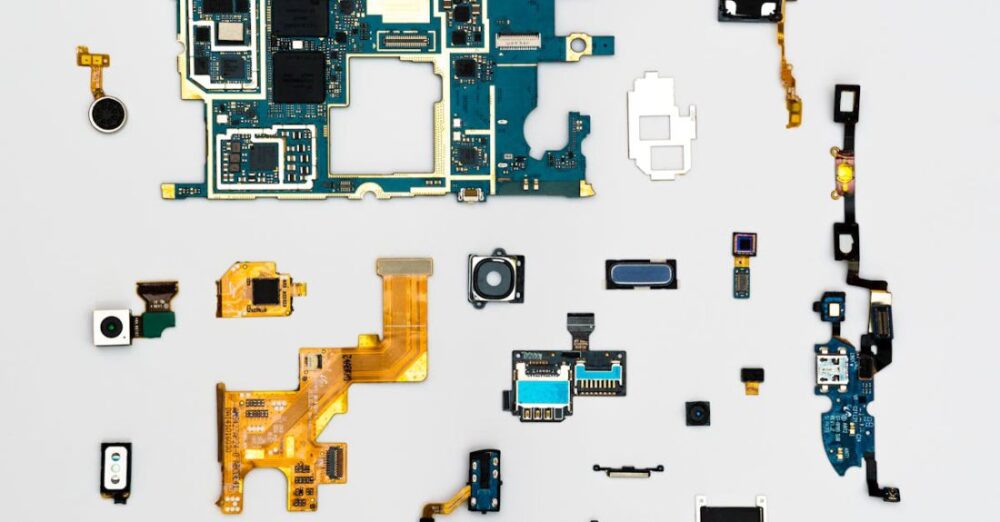

The world of manufacturing is undergoing a significant transformation with the integration of robotics into production processes. The advent of robotics in manufacturing has revolutionized the industry, leading to increased efficiency, precision, and productivity. From assembly lines to material handling, robotics has proven to be a game-changer in streamlining operations and driving innovation. Let’s delve into how robotics are reshaping the landscape of manufacturing.

Enhanced Efficiency and Productivity

One of the most significant advantages of robotics in manufacturing is the enhanced efficiency and productivity it brings to the table. Robots are capable of working tirelessly around the clock, without the need for breaks or rest, leading to a substantial increase in production output. With their speed and precision, robots can perform tasks much faster and with greater accuracy than human workers, resulting in higher productivity levels. This efficiency allows manufacturers to meet increasing demands and deadlines more effectively, ultimately driving business growth.

Improved Quality Control

Quality control is a critical aspect of manufacturing, and robotics play a vital role in ensuring consistent and high-quality products. Robots are programmed to perform tasks with precision and accuracy, reducing the margin of error in the production process. They can conduct intricate inspections and measurements with utmost precision, detecting even the smallest deviations in products. This meticulous quality control not only helps in maintaining high product standards but also minimizes defects and waste, ultimately saving time and resources for manufacturers.

Flexible Automation

Another key benefit of robotics in manufacturing is the flexibility they offer in automation. Unlike traditional automated systems that are rigid and specialized for specific tasks, robots can be easily reprogrammed and adapted to perform a variety of functions. This flexibility allows manufacturers to quickly switch between different products and processes, making their operations more agile and responsive to changing market demands. By integrating robotics into their manufacturing processes, companies can achieve a higher degree of flexibility and customization, catering to a wider range of products and customer needs.

Safety and Ergonomics

Safety is a top priority in manufacturing environments, and robotics play a crucial role in ensuring a safe working environment for employees. By taking over hazardous or repetitive tasks, robots help reduce the risk of workplace accidents and injuries, improving overall safety standards. Moreover, robots can handle heavy loads and perform physically demanding tasks that may pose health risks to human workers. This not only enhances safety but also improves ergonomics in the workplace, reducing the strain on human workers and minimizing the risk of musculoskeletal disorders.

Cost Savings and Return on Investment

While the initial investment in robotics may seem significant, the long-term cost savings and return on investment are substantial for manufacturers. Robots can operate continuously and efficiently, leading to lower labor costs and increased production output. Additionally, robots require minimal maintenance and have a longer operational lifespan, reducing downtime and repair expenses. Over time, the efficiency, productivity, and quality improvements brought about by robotics result in significant cost savings and a positive return on investment for manufacturing companies.

Driving Innovation and Competitiveness

In today’s rapidly evolving market landscape, innovation is key to staying competitive, and robotics are driving innovation in manufacturing. By leveraging advanced technologies such as artificial intelligence and machine learning, robots are becoming smarter and more autonomous, capable of making real-time decisions and adapting to dynamic production environments. This innovation not only enhances efficiency and productivity but also opens up new possibilities for product design, customization, and process optimization. By embracing robotics, manufacturers can stay ahead of the curve, differentiate themselves in the market, and maintain a competitive edge.

In Conclusion

The integration of robotics in manufacturing is revolutionizing the industry in more ways than one. From enhancing efficiency and productivity to improving quality control and safety, robotics are reshaping the manufacturing landscape and driving innovation. As technology continues to advance, the role of robotics in manufacturing will only grow, offering manufacturers new opportunities to optimize their operations, innovate their products, and stay competitive in an ever-changing market. Embracing robotics is not just a trend but a necessity for manufacturers looking to thrive in the digital age.